Part Selection Guide

Passive Parts

C1 (film)

If you use the schematic value for R2, 499 kΩ, this cap can be as small as 0.1 µF and still give acceptable performance. This allows for even big audiophile caps to fit here, if your enclosure is large enough. Thus, there isn’t a problem getting adequate sound quality while still having a large enough capacitor here to leave the bass frequencies relatively unscathed.

There’s an artificial dilemma if you want to use a smaller pot than 50 kΩ. That allows you to lower the value of R2 to decrease its contribution to the amp’s noise floor, but then you have to increase the value of C1 proportionally to achieve the same bass performance. Say you want to use a 10 kΩ pot, allowing a reduction of R2 to 100 kΩ. You would then have to use a 0.47 µF C1 to get approximately the same bass frequency behavior as with the above situation. But, this will mean either a cap that’s physically 4.7× as large, or not as good as the 0.1 µF you could have fit into the same space. You might choose to stick with the 499 kΩ R2 even with a 10 kΩ pot so you can use a high-quality 0.1 µF C1, trading a slightly higher noise floor for better overall sound quality.

Even the best quality capacitors damage the sound to some extent. You can avoid that damage and dilemmas like the above by jumpering this part, but that has its own risks. I go into details in a separate article, Input Capacitors for Headphone Amps.

If you don’t jumper this position, it’s best to use polypropylene capacitors here, or Teflon if you can find and afford them. Next down the scale are PPS film and polycarbonate. Even farther down are polyester, but you should only use those if space is at an absolute premium and you can’t use PPS chip caps.

Optional? Yes, jumper it.

Largest Part Size: 15 mm × 7 mm with 5, 7.5, 10 or 12.5 mm pin pitch for thru-hole caps, or 1210 for SMT

C2 (electrolytic)

These are the main power reservoir capacitors, also called the “rail capacitors,” because they span the power rails.

The board will hold between one and three caps, in parallel:

There are four supported ways to mount just one rail cap on the PIMETA v2 board:

- use a 10 or 12.5 mm diameter cap in C2A

- do the same in C2B

- run a 16 or 18 mm diameter cap from the V- pin of C2A to the extra B+ pad between these two caps, shown at right

- do the same between C2B’s V- pad and the extra B+ pad

These configurations are all electrically identical. The choice between them is really just a parts availability question. Beware that when using 16 or 18 mm diameter caps, they will hang over the edge of the board, a bit.

The easy choice is to use two caps, populating both C2A and C2B, using either 12.5 mm or 10 mm caps, as described above. This gives lower ESR than the previous configuration, all else being equal.

You can get even lower ESR by adding a third C2 cap in the scratchpad area, as shown at right. You can use the extra lead length on the cap to stretch to the provided B+ and V- pads, or you can use hookup wire to make these jumps. If you take the former path, I recommend using heat shrink on the exposed parts of the leads to avoid short circuits; this is the amp’s power supply, remember!

If you use more than one cap for C2, the values add and their ESR and ESL are divided by the number of capacitors, giving better overall performance than if you had used just one of those caps. Therefore, if you ignore capacitor quality issues, the third option above will give the best performance. The second option lets you use the scratchpad area for other things, though, and will still give fine performance. Using just a single cap is okay, but only a performance option if you’re using a really nice cap here, such as a big 18 mm unit.

Capacitors in the 220 µF to 1000 µF range will serve you best here. These caps are in parallel, so their values add together; your total capacitance should be in the 400 to 2000 µF range, roughly. Use too little capacitance here, and bass performance will suffer. Use too much, and you can cause difficultites for the power supply; even if not, it probably means you’ve compromised too much on quality. Generally speaking, higher quality capacitors have a lower capacitance density: given two caps with the same “can” size and voltage rating, if one is a 220 µF cap and the other 330 µF, the former is probably the better cap. You end up trading off maximum bass response (less capacitance) to get higher quality caps for better overall sound quality. It’s quite likely that two or three good 470 µF caps will sound better than a single low-quality 2200 µF cap.

Use caps with a voltage rating higher than your power supply’s voltage here, but no higher than necessary. For example, use a 25 V capacitor if your power supply is 24 V. Using a 35 V cap instead would be wasteful, and a 16 V cap would pop soon after plugging the power supply in.

C2A and C2B are sized for 12.5 mm diameter caps. You can also use 10 mm caps in these positions, as they have the same pin pitch, but that means sacrificing quality or capacity. You might choose to do that anyway, though, either to save space or because you can’t find 12.5 mm diameter caps that you like.

I recommend the Panasonic FM, Panasonic FC, and Nichicon PW lines here: low ESR, long life, and fairly high capacitance density. The Panasonic FC and the Nichicon PW are identical, specwise. The Panasonic FMs are a little nicer than the FCs, but there are fewer values and fewer case size choices in that line. If your chosen distributor doesn’t carry one of these lines, try to find a cap line with similar qualities.

If you have prior experience with the META42 and PIMETA v1 designs, beware that unlike those designs, the full power supply voltage is across these caps in PIMETA v2. (Perhaps less one diode drop.)

Optional? No; populate at least one cap. If you don’t use both C2 positions, leave the other one open; don’t jumper.

Largest Part Size: 18 mm diameter for a single cap, or 12.5 mm for two or three

C3, C5 (film, ceramic)

These are bypass caps for the op-amps, and to a lesser extent the buffers.

Surface-mount multi-layer ceramic caps (MLCC) work best here. Next best are leaded ceramics, followed by polyester film box caps. Film box caps have better linearity than the ceramics, but I rank them lower because they will physically interfere with the use of BrownDog adapters, and make removing chips from sockets more difficult. If you’re worried about linearity, choose C0G or NP0 dielectric ceramics, rather than X, Y or Z series ceramic dielectrics.

0.1 µF caps will work for almost all situations.

Optional? With slow, docile op-amps, yes, but not recommended. May be absolutely required with some op-amps. Leave out, don’t jumper.

Largest Part Size: 1206 for surface-mount caps, 5 mm × 2.5 mm for leaded caps

C4 (film or tantalum)

These are the high-speed reservoir caps. Electrically speaking, they sit between the rail caps and the bypass caps, being faster than the former and bulkier but farther away from the chips than the latter. They primarily serve to improve the dynamic performance of the amp.

Unlike with the preceding headphone amp designs — the PIMETA v1 and the META42 — these caps are only optional if you leave out the bypass caps. By adding these caps in PIMETA v2, we added a risk of running into a limitation of the TLE2426, which is that it can be unstable with between about 0.001 µF and 0.47 µF on its output. (See the graph on page 17 of the TLE2426 datasheet.) The default bypass cap configuration puts 0.2 µF here, well within this danger envelope. I recommend using at least 1 µF in C4 to push the amp well past the upper edge of this envelope.

You can readily find 1 µF PCM-5 metalized polyester box caps which fit here. However, we’ve set aside more space than is strictly required for C4 because it lets you move beyond merely keeping the TLE2426 stable into an actual improvement in performance. PCM-5 box caps up to about 2.2 µF are widely available. In my humble opinion, the best cap to use here is the 10 µF/50 V Wima MKS-2. I think it’s a worthwhile step up from the smaller caps you can find most other places.

Most film caps will have at least a 50 V tolerance, and even that is atypically low, with 63 V and up being more common. The higher the voltage tolerance, the less capacity you get in a given volume, so as long as you exceed your power supply voltage, there’s no value in going higher. A rare few cap lines will have tolerances below 50 V, even down into the typical power supply range for a PIMETA. There’s a 10 µF/16 V cap in the Wima MKS-2 line with the same case size as the 6.8 µF/50 V mentioned above, but it restricts you to a power supply voltage of 15 V or less.

Tantalum caps should also work here. Easiest to use are 7343 surface-mount caps, as there are pads for this on the bottom side of the board. You can also use leaded caps, but you’ll want to get them with formed 0.2" pitch leads. If you get tantalum caps with straight leads, you would have to bend them out by hand to fit; I find that you risk cracking the outer shell when you do that, which probably isn’t good for the cap.

Optional? Only if you also leave out the bypass caps. Do not jumper.

Largest Part Size: 9 mm × 7.5 mm

C6 (NP0 or C0G ceramic)

These caps can improve the amp’s performance, in some cases even to the point of saving an amp that won’t work without them. You need to do a square wave test to find out whether you actually need these caps and what value they should have.

If you don’t have the equipment or patience necessary to test for the right values, I recommend 4.7 to 10 pF for all three caps.

If you do the square wave test, you’ll find that you can minimize ringing in the square wave with a cap somewhere in the 1 pF to 100 pF range. Generally sepaking, the faster the op-amp and the lower its gain, the larger the cap value you need to use. Because of this dependence on chip type and gain, the optimal value for the ground channel is likely different than the one for the left and right channels.

Only C6G has a labeled footprint on the board. C6L and C6R don’t need their own places on the board, because the R6L and R6R positions actually provide two footprints already: one thru-hole on the top side of the board and one surface-mount on the bottom side underneath the thru-hole position. I suggest you pick the R6 part type to match the other resistors, then use the other package style for the caps. If you want to be tricky about it, you could stack thru-hole or surface-mount parts on the same side of the board instead.

Beware that the thru-hole footprint for C6G is smaller than for C6L & R, but that both use the same SMT footprint. This difference is simply due to layout restrictions.

This cap is directly in the signal path, so don’t use cheap X, Y or Z series ceramic dielectrics here. Use only NP0 or C0G.

Optional? No. As explained above, while it may be that you can test and prove that they aren’t required, this requires equipment that most DIYers don’t possess and time that even those who do have the equipment often don’t want to spend. Since these caps are at worst harmless, I consider them non-optional.

Largest Part Size: 0.2 in (5 mm) pitch leaded cap for C6G, 0.3 in (7.5 mm) for C6L/R, or 1206 surface-mount for all three

D1, D2

These diodes prevent damage to the amp if the power supply is connected backwards, and channel the various power supply currents to avoid bad behvaior like the batteries trying to discharge through the wall supply.

Both diodes are required if your amp will be using the built-in NiMH trickle charger, as it keeps the wall supply and NiMH battery from fighting with each other. If your amp will have just one power supply type, you don’t need either diode, though installing the one in series with that supply’s connector is still recommended, to prevent damage in case of a reversed supply connection. For wall-powered amps, add D1 to get this feature, and add D2 for battery-powered amps.

Any old silicon diode will work here, as long as it has a suitable voltage tolerance. Schottky diodes are not recommended unless you’re striving for the absolute lowest supply voltage possible and aren’t willing or able to give up the protections these diodes provide. Otherwise, the lower leakage of a silicon diode will be preferrable.

Optional? Yes, do not jumper.

IC1

This is an LM317, part of the NiMH trickle charger.

The board footprint is sized for a TO-220 packaged regulator. You need such a big package when trickle charging larger cells, such as AAs and AAAs. For small cells, like those in “9 V” rechargeables, you can get away with a TO-92 version of the LM317. You just need to splay the legs a bit to make them fit in the wider pin spacing.

You can use any generic LM317 here; there’s little value in using something special for this.

If you don’t want the charger, simply leave this part out.

IC2

This is a TO-92-packaged TLE2426, discussed elsewhere, including info on how and whether to leave it out.

LED1

This LED’s primary purpose is to act as a stable voltage reference for the adjustable class A biasing circuit. The voltage drop across an LED doesn’t change much as a function of the current through it, nor does the VBE drop in a transistor, so there is a nearly constant voltage across RBIAS + RBLIM. A constant voltage across a constant resistance gives a constant current, just what you want for class A biasing.

This LED can also act as a power indicator, or interior illumination inside your amp’s enclosure. Its brightness is set by RLED.

The footprint on the board accepts standard 5 mm LEDs, but you can also use 3 mm LEDs by bending the legs out a bit. If you board-mount the LED, you probably don’t want it to sit right down on the board, as you’re probably using it for interior case illumination, so you’ll get wider illumination by letting it “float” a little above board level.

You can panel-mount the LED, using various sorts of LED lenses and holders, with hookup wire to attach it to the board.

If you want class A op-amp biasing but no LED, you can replace this with a string of two or three silicon diodes in series, as shown at right. If you do so, RLED can keep the same value as you might choose for an LED to give performance near as good as using an LED. Or, you can choose a much higher value for RLED and get merely decent biasing performance with less waste current.

LED2

This is an alternative to LED1, or an addition to it. It’s in the constant-current leg of the class A biasing circuit, so it will always be a constant brightness, regardless of changes to the power supply voltage.

To use LED2 instead of LED1, but still have class A biasing, use a diode string in place of LED1, as discussed above.

To use LED2 instead of LED1 without class A biasing, leave out Q2, Q3L, and Q3R, turning the class A biasing circuit into a constant-brightness driver for LED2.

To use LED1 and LED2 together, you don’t have to do anything special, but you might consider the constant-current options discussed at the bottom of the RLED section if you’re using a battery supply. Otherwise, as LED1 is dimming as the battery runs down, LED2 will have constant brightness, not likely to be what you want. You probably want both to have the same constant brightness.

Q1, small-signal PNP

This transistor is part of the adjustable current source used to bias the op-amps into class A. (Click that link for an explanation of how this works.)

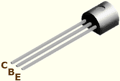

This part needs to be a small-signal PNP transistor in the TO-92 package. The 2N3906 and the 2N5087 are known to work, as should the PN2907. These are all very common, here in the US at least. If you can’t find these recommended transistors, be assured that there are plenty of suitable alternatives. This circuit is not very particular about the sorts of transistors that will work. The only trick is making sure the pin order is correct. We designed the PIMETA v2 to use transistors with the US standard pinout, as seen to the right. Small-signal transistors with part numbers beginning with “2N” or “PN” are likely to use this pinout.

That pinout is, alas, not universal. European transistors (part numbers typically beginning with “BC”) most often use a pinout exactly backwards relative to US transistors. As a result, you can still use them by just installing them in the board opposite the way the silkscreen outline on the board suggests. Japanese transistors (typically numbered beginning with “2S”) are more trouble to make work with a PIMETA v2 board than it’s worth, because they typically use still another pinout, so to make them work you’d have to bend leads around to get the right pin order.

Q2, Q3L, Q3R, small-signal NPN

These transistors are part of the circuit that biases the op-amps into class A.

The Q1 discussion above applies equally to these transistors, except that you’re looking for NPNs in these board positions. Common transistors similar to those recommended above are the 2N3904, 2N5088, and PN2222.

R1

The main purpose of R1 is to help balance the op-amps’ input impedances. Use the value on the schematic unless you have a good reason not to. If you do change it, it needs to be the same in all three channels, and it should be equal to R3 + R5. It is not essential that this relationship be maintained, but not doing so can increase distortion by a tiny amount.

In the left and right channels, R1 interacts with R2 to form a voltage divider. If R1 is much smaller than R2, this effect is negligible, which is the way you’ll almost certainly want it. In rare situations, one might choose to configure this to divide the voltage down by a significant amount on purpose.

Optional? Technically yes, in which case you’d jumper it, but I recommend you always populate it.

R2 (left and right channels only)

This resistor lowers the input impedance of the amp to avoid RFI noise pickup problems. It also prevents a weird sort of DC offset problem when C1 is installed.

R2 should be around 10× the value of your volume control; the exact value is not critical. The lower you go, the more your source will see the amp as a varying impedance load as you rotate the volume knob. This may cause it to have different sound characteristics at different volume levels. It’s better to go high than low. You don’t want to go too high, though, because the larger the value, the more thermoelectric noise gets added to the circuit. Noise added here, at the input stage, gets multiplied by the amp’s gain, so it’s the worst possible place to have a noise source.

The schematic value of 499 kΩ assumes you will use a 50 kΩ volume control. The flexibility in the value here means 470 kΩ, 510 kΩ and 560 kΩ are also reasonable values, with 1 MΩ being the upper sane limit. 1 MΩ would be fine for a 100 kΩ pot — the highest pot value recommended — or 100 kΩ here for a 10 kΩ pot — the lowest pot value recommended.

Optional? No.

R3, R4, R5, R6 (left and right channels only)

These are the feedback resistors. They set the amplifier topology and the gain. The standard topology uses all four positions, and is called the Jung multiloop topology, named after Walt Multiloop...I mean Jung.

There are a alternative topologies, but the only common case where you’ll use one is when leaving out the buffers.

The simplest path is to just use the values given on the schematic. Next simplest is to leave R3, R5 and R6 at their default values and adjust R4 to change gain. (Gain calculator.) If you want to fiddle with everything, read about how to optimize the multiloop values.

Optional? For a standard configuration, populate all four positions.

R4G

Same value as for R1G.

Optional? No.

R7

This resistor avoids unwanted interactions between the op-amp output and the input capacitance of the buffer. There is a range of useful values here for a given op-amp choice, but the datasheet value, 100 Ω, seems to work with a wide variety of chips. If you’re using a chip that makes the amp oscillate, there’s a formula on page 15 in the LMH6321 datasheet for calculating a resistor that should fix this.

Optional? No.

R11

This resistor is for adjusting the behavior of the buffer’s current limiting circuit.

If you leave this resistor out, the buffer will have no output current limiting, which means it sounds as good as possible, but also that it can be damaged if the output is ever shorted while there is an output signal. Since most headphone jacks will short the right channel to ground briefly while inserting or removing the headphones, this is easier to do than you might have guessed. So, if you leave out R11, never plug or unplug the headphones while music is playing.

The equation for selecting this resistor’s value for a given maximum output current is:

`R11 = \frac{200 V_+}{I_{max}}`

Flipping it around to predict the maximum output current, given an R11 value and the total supply voltage, we get:

`I_{max} = \frac{200 V_+}{R11}`

The maximum safe output current for this buffer is 300 mA, and the output current limit increases as the resistor value increases, so the smallest safe value for R11 is 667 times your power supply voltage. These formulas are based on single-voltage power supplies, so if your power supply is 24 V, use 24 for V+, not 12, as you would if it were referring to the ±12 split supply. This is why the formulas above differ from the ones in the datasheet, by the way; National’s formulas assume a split supply.

Beware that it’s possible to hurt the quality of the sound by using too high a value here, causing the current-limiting circuitry to kick in on dynamic peaks.

Unlike most of the resistors on the board, this one only accepts tiny ⅛ W leaded resistors. That is, those with a body length under 0.2", that being the pin pitch. You can still use 1206 surface-mount resistors on the bottom side of the board, like most of the other resistors, however.

Optional? Yes, leave out.

RBIAS, RBLIM

These parts set the current used for biasing the op-amps into class A.

RBLIM stands for Resistor, Bias LIMit, since it sets the upper limit on the amount of bias current. Without this resistor, you could dial RBIAS down to very low values, giving far higher bias currents than could ever be useful. RBLIM = (Vf - VBE) ÷ I, where Vf is the forward voltage drop of LED1, VBE is the drop from base to emitter of Q1, and I is the desired maximum bias current. Or to go the other way: I = (Vf - VBE) ÷ RBLIM. Therefore, the values on the schematic give a 3 mA floor, approximately, comfortably higher than the greatest conceivably useful class A biasing current in this circuit.

RBIAS is a multi-turn trim pot in series with RBLIM. It can only decrease the bias current by increasing the resistance over the high point set by RBLIM. Just add its value to that of RBLIM in the formulas above if you want to calculate how it changes things. Typically you want to adjust it to give around 1 mA of bias, but being a trim pot, it gives you the freedom to play with this value.

The schematic shows 5 kΩ for RBIAS, as it gives you enough reach to hit the common 1 mA bias current, which a smaller pot wouldn’t allow, without increasing RBLIM to compensate. You might go with an even higher value, either because you want to try really low bias currents, or because you want small adjustments to the pot to give bigger effects than with a smaller pot. With a mythical 3 kΩ 10-turn trim pot, each turn is 1 mA of bias, pretty fine. A 10 kΩ 10-turn trim pot would let you trade some accuracy to get to a given bias point 2 times faster than with the default 5 kΩ trim pot.

Adjustability isn’t really necessary. If you know in advance what class A biasing current you want, it’s easy to calculate the proper resistor value using the formulas above. In that case, you can just use a resistor straddling from one end of RBLIM to the far end of RBIAS, as shown at right. That’s why the pads are more or less aligned on the board. You just treat it as if the footprint on the board were excessively large.

Largest Part Size: 0.2 in × 0.375 in (5 mm × 9.5 mm)

RCCS

This resistor sets the battery charging current. (The name stands for Resistor, Charge-Current Set.)

See the NiMH trickle charger section of the docs for an explanation of how to set this up, including picking the value for this resistor.

Unlike most of the resistors on the board, this position can take up to a ½ W leaded resistor, or a 1210 size surface-mount resistor. You may be able to use the same resistor type you use in most other positions on the board, if your charging current is low enough. That is to say, you’re using small NiMH cells, like those in a “9 V” rechargeable. The power dissipation in this resistor is the resistor value divided into 1.56. For instance, if you want to use a 6.2 Ω resistor here, the dissipation will be just over ¼ W, so you’d want to use a ½ W resistor here, for sure. I recommend over-specing this resistor by at least 2×, if possible. That is, you’d only want to use a ¼ W resistor here if the charge current causes no more than ⅛ W of power dissipation in this resistor. Bigger resistors are cheap enough that it’s not worth pushing the limits here.

RLED

This is LED1’s current limiting resistor. Use Ohm’s law to figure current given the LED’s voltage drop and the power supply voltage. For example, consider a 1.8 V LED with a 15 V power supply and a 4.7 kΩ RLED:

I = V/R

I = (15 - 1.8) / 4700

I = 0.0028

So, 2.8 mA goes through the LED.

Most LEDs require 1 mA to achieve a minimally useful brightness level. More current gets you more brightness, but of course uses more power, which mainly matters with battery power supplies. Most LEDs are rated for at least 20 mA, but that’s annoyingly bright for a power indicator. I never go beyond 5 mA for a simple power indicator, myself.

For power supply voltages typical in a PIMETA, you will probably use something in the 1 kΩ to 10 kΩ range. I often use 2.2 kΩ or 4.7 kΩ.

You could put some kind of constant current source here in place of the resistor, so that the LED brightness remains constant regardless of battery level. Once upon a time, there was a class of device of this sort called a CRD which was available in a resistor-like 2-lead axial package, but these have become really hard to find. You can make your own CRD from a JFET, but the process involves a tedious hour or so of measuring and sorting. My article on biasing op-amps into class A should give you the clues you need to do this, if you want.

Optional? Yes. Jumper only if your LED has an integral resistor. Most don’t.

Resistor Types

As a rule, you should be using 1% film resistors for this build. 5% carbon resistors are cheaper, but the cost savings just isn’t worth it. Carbon resistors are noisier than metal film resistors, and the gain setting resistor ratio on each channel must be close enough that you don’t hear an audible mismatch between the channels.

If you have a fairly accurate meter, you may want to hand-match your resistors.

Resistor brand isn’t critical, but I happen to like the Vishay-Dale RN/CMF series for projects like this. I’ve measured thousands of the things over the years, and they always test well within their rated specs. I also like the fact that they use a numeric resistor code instead of the more common colored stripe code; I find numeric codes easier to read. Generic MFRs are fine for the PIMETA v2, though.

The only places I'd use cheap resistors in a PIMETA v2 are in RCCS, RLED and RBLIM.

Resistor Sizes

Most of the resistor positions on the board will accept standard ¼ W resistors, but that’s only because they’re the most readily available sort, not because we actually expect this much current. These footprints accept leaded (thru-hole) resistors with 0.3" pin spacing (7.5 mm) on the top side of the board, or 1206 surface-mount resistors on the bottom side of the board.

There are two exceptions.

The R11 holes are only 0.2 in apart (5 mm), as there isn’t room here for larger resistors. This is fine, as these resistors only funnel very tiny amounts of current into the buffers’ current-limiting circuit. The surface-mount pads on the bottom side still accept 1206 size resistors, for convenience, not because you really need resistors this big. You can use 0805 if it makes you happy to use small resistors here.

The RCCS holes are 0.4 in apart (10 mm), allowing up to ½ W thru-hole resistors, or 1210 size surface-mount resistors on the bottom side. This is because this resistor is unique in that it can see more than ¼ W in normal operation. (See the RCCS discussion above for the formula to calculate power dissipation in this resistor.)

If you use Vishay Dale CMF series resistors, beware that they are typically rated for half the wattage of their similarly-sized generic cousins. This is because of their extended mil-spec temperature range. For the temperature range you will encounter in a properly-functioning amp, they are equivalent in power handling capacity to generic resistors. Use the RN55 series for most positions on the board, RN50 for R11, and up to RN60 for RCCS.

About the Buffers

The buffers sit between the op-amps and the headphone load. They handle the headphones’ high dynamic current requirements so the op-amps can focus on what they do best: accurate, low-distortion voltage amplification. It is possible to build a working PIMETA v2 without buffers, but this shifts the headphone load to the op-amps, increasing their distortion. To keep this under control, you need to use exceptionally strong op-amps, else you risk losing much of the high-end value potential in the PIMETA v2 design.

There is no standard buffer pin-out, not even a de facto one. The board was designed for the National Semiconductor LMH6321MR, and that remains the only buffer known to work directly with the board. It’s possible to adapt other buffers to use the LMH6321 pinout, but it seems to me that there’s little reason to do so. This chip is as readily available as any other good-sounding buffer, and it is among the best in terms of sound quality.

Choosing Your Op-Amps

There are three op-amps in the PIMETA circuit: one each in the left, right and ground channels.

The left and right channels are served by a dual-channel chip, OPALR. If you want to use single-channel chips, BrownDog offers adapters that take two DIP-8 or two SOIC-8 op-amp chips and adapts them to work in the DIP-8 pinout of OPALR.

The ground channel is served by a single-channel op-amp, OPAG. You can use the single-channel version of the op-amp you used in OPALR, but this is not required. See below for comments on using a different type of chip in OPAG than in OPALR.

The PIMETA board accepts both DIP-8 and SOIC-8 packaged op-amps. The SOIC-8 pads are nested within the DIP-8 footprints, on the bottom side of the board.

When in doubt, I recommend using DIP-8 op-amps, because they’re easier to solder and let you use sockets. Sockets then let you roll op-amps easily, and swap them if they become damaged. Additionally, they remove the possibility of overheating the chip with your soldering iron, since the socket takes the heat; the worst you can do is melt a cheap socket. If you want to use an op-amp that’s only available in SOIC-8 form, you can still use sockets by first adapting the op-amp to DIP-8 with the Brown Dog straight SO-8 to DIP-8 adapter.

Sockets and adapters can cause problems. They add lots of little tiny “parasitic” resistances, capacitances and inductances to the circuitry around the op-amp. The slower the chip, the less likely these parasitics will matter. Generally speaking, it’s best to solder the op-amps directly to the board when they’re around 100 MHz or faster.

While most any op-amp can be made to work in the PIMETA board, FET-input op-amps are the easiest sort to use. All of the parts recommended in the part list are of this type. The most common op-amps have bipolar transistor inputs instead, which you can’t drop into the stock design without changes, lest you risk high DC offsets at the output of the amp.

OPALR does all the voltage amplification in the PIMETA circuit. This chip has the single biggest effect on the amp’s sonic signature, so pick this part carefully.

OPAG also affects the amp’s sonic signature, but not as much as OPALR. Some argue that you should use the single-channel version of the chip you used for OPALR in OPAG; the theory goes that because the ground channel must counteract the currents created by the left and right channels, using the same type of chip in all three channels is likely to give the lowest distortion since they all react to the signal in the same way. What we find in practice is that because both contribute to the sound of the amp, using dissimilar chips in OPAG and OPALR lets us fine tune the amp’s sonic signature more finely than if we always use the same chips for all channels. There is no practical limit on how widely different your OPALR and OPAG chips can be, as long as each is compatible with the PIMETA v2 circuit as a whole.

You may actually be forced to use a different type of chip in OPAG than in OPALR. Perhaps your OPALR chip of choice doesn’t come in a single-channel version, such as the OPA2107. Or, maybe the op-amp you’re using in OPALR isn’t unity-gain compensated (e.g. OPA637, OPA228) and so won’t work in the ground channel. These two examples do come in unity-gain-stable compensated versions (OPA627 and OPA227, respectively) but they don’t sound exactly the same as their faster uncompensated cousins.

The canonical parts for this amp are the Analog Devices AD8620 for OPALR and the AD8610 for OPAG. They are reasonably priced, sound very good, are readily available, have low current draw, and work down to lower supply voltages than many other good audio op-amps. While I wouldn’t call this chip “aggressive,” it is quite detailed, especially at high frequencies. This may mate well with your system and music or it may reveal problems you’d rather hide.

Mellower chips that are known to work in this amp are the AD843 and OPA637/627. The AD8066/8065 worked well in the PIMETA v1 and should also work in the v2. For reviews and more recommendations, see the companion article, Notes on Audio Op-Amps.

If you’re planning on using uncommon op-amp types, I recommend that you read the companion article, Working with Cranky Op-Amps first.

Choosing a Volume Control

There are a few things you need to look for when choosing a volume control. First, it needs to be a dual-gang audio (or “log”) taper type. Second, it shouldn’t be any lower in value than 10 kΩ, or any higher than 100 kΩ. The lower the better, generally, but 10 kΩ probably won’t work well with some vintage audio equipment, or tube equipment. 100 kΩ should work with anything, but the higher the value, the more noise you get. 50 kΩ is a good all-round compromise. (The benchmarks use a 50 kΩ RK27.)

The PIMETA v2 directly supports two different types of potentiometers (pots) and one popular type of stepped attenuator:

ALPS RK097/8: I consider this the standard pot for the PIMETA v2. I like it because it’s cheap, small, good quality, and there is a version available with a built-in power switch. The ALPS RK09 line is very broad, so be sure you’re getting the right part. In particular, be sure the part number begins with RK097 or RK098. ALPS also has the RK09D and RK09K series, which are in fact cheap clones of the Panasonic EVJ. (Confused yet?) This EVJ clone line doesn’t have an option for threaded bushings so they’re unsuited to DIY. Beware that the power switch is optional in the RK097 series, and most places that carry pots in this line don’t carry the one with the swtich.

ALPS RK27: I carry this in my parts shop, too, the 50 kΩ version. It’s a lot larger and more expensive than the RK097, and it’s missing the built-in switch, but it offers much better performance at a reasonable price. Besides my shop, you can get these from AMB Audio Shop (US, ships worldwide), Mouser (US, ships worldwide), Angela Instruments (US, ships worldwide), RS Components (worldwide, except US; part# 236-9604), Rapid Electronics (UK; part# 66-0225), and THLAudio (Taiwan, ships worldwide).

DACT CT2: When you must have the very best, you use a stepped attenuator, not a pot. (See this for the reasons why.) The CT2 is even bigger than the ALPS RK27, but as SAs go, it’s pretty compact. Sadly, so is the PIMETA board, and therein lies a conflict. The back end of the CT2 extends a little into the space set aside on the board for the S1 and INPUTS connectors, and for C4-. If you don’t use the connectors and either leave out the C4s or use small enough caps (e.g. tantalum SMDs on the bottom side), there’s no problem. Beware that leaving out C4 entirely means you also have to leave out the bypass caps to keep the TLE2426 stable, and that restricts the types of op-amps you can use safely. It may be possible to build some sort of riser rig to lift the CT2 far enough away from the board to let you use the recommended film caps in C4, or simply mount it off-board and connect it to the board with hookup wires.

There are many other choices that will also work. In addition to the general advice given at the top of this section, you have to work out the physical compatibility issues.

Many small audio pots have 6 pins arranged the same way as on the RK097, so they might just drop in. The main thing to look out for is that there is no standard for the distance between the front row of pins and the mounting surface. This will matter if your enclosure doesn’t leave much room around the board.

You don’t have to use a pot with a pinout like those recommended above. You can mount the pot to the front panel, the PIMETA board to the bottom of the case, and run wires between the two. If you’re just going to solder wires between the two, I recommend using the ALPS RK27 pads, as they’re nice and big, and so will accept good, thick hookup wire. Another option you should consider is using standard 0.1" pitch connectors, which is covered elsewhere.

Choosing an Enclosure

The PIMETA board was designed to fit in the Serpac H-65 series enclosures. In particular, I recommend the version with a 9 V battery compartment. This slim case doesn’t offer much room for creative additions, but it does make for a nice, pocketable amplifier. Easy access to the battery makes it great for use with lithium rechargeables, too, since the PIMETA v2’s built-in charging circuit only supports nickel chemistries. The ALPS RK097 pot works nicely with this case. Simply center the pot hole on the front panel in both directions. The mounting nut will just barely fit between the top and bottom lips around the panel this way.

There is a related Serpac enclosure, the H-67, which is the same size as the H-65, only taller. It’s not big enough to allow for the ALPS RK27 or DACT CT2, even with creative mounting. The H-67 has a more limited color selection than the H-65. One interesting option you have with this enclosure is that there is a version with the battery door but just empty space behind it, so you can stuff two 9 V batteries in there, connected to the PIMETA board with snap leads. (The H-67-9V variant has just a single 9 V battery holder.) The PIMETA has dual power supply pads set up for series connection, so this makes an easy way to set up a PIMETA with an 18 V supply. You will have to put a little foam in there to prevent the batteries from rattling around, though. Another virtue of this enclosure is that there’s room in there for a single-level crossfeed circuit, if you use half-inch standoffs, polyester box caps, and mount the crossfeed board with the components downward.

Internal Connectors

The footprints on the PCB for S1, INPUTS, WALL and BATT are sized for Molex KK series straight connectors with 0.1" pin spacing. (Beware, there’s also an 0.156" pin spacing variant.) The part numbers given in the part list are for the generic tin-plated ones. There are gold plated variants, plus versions with and without the locking tab, right-angled variants, etc. The product series is broad and deep enough that you can get a little lost in there if you’re not careful.

The quantities given in the part list only cover the explicit footprints on the PCB. You may need or want more than called out. Adding more Molex connectors is a big part of building for tweakability. In that case, don’t forget to get more crimp pins, too. In fact, be sure to get more pins anyway, in case you have to change some wires around; it’s more bother than it’s worth to try and remove and reuse these pins.

If you plan on doing more than just this one project, I highly recommend that you get a KK compatible crimp tool. There are several to choose from; I recommend Molex part #63811-1000. You can use needlenose pliers instead, but they won’t give as secure an attachment. Soldering solves that problem, though that adds more work than just using a proper crimper to begin with, and begs the question of why you’re not just soldering the wires to the board. A proper KK type crimper folds the pin tabs around in a way that makes for more surface contact area between the pin and wire than you can achieve with pliers, all but eliminmating the chance that tugging on the wire will break the connection. The recommended tool is inexpensive, as specialty crimpers go.

Don’t bother getting the official extraction tool. You just need a thin-bladed screwdriver to release the pins from the connector shell. Molex’s tool does this in a more clever way, but that’s not enough to justify the $8 they want for a stamped-out piece of sheet metal.

Choosing a Headphone Output Jack

If you’re using a metal case, your output jack needs to be an isolated type. A non-isolated jack connects the ground connection to the chassis; since the chassis is probably tied to virtual ground (i.e. input ground) through the pot or the input jacks, this will short out the ground channel. At best, shorting out the ground channel makes it useless, and at worst it will cause instability in the ground channel.

The easiest type of jack to deal with is fully isolated, like the Neutrik NJ3FP6C and Switchcraft N112B, mentioned in the parts list. (The Neutrik jack has a metal body, but the ground connection isn’t tied to it.) Another common type has plastic mounting threads but there’s a metal contact that goes to ground and is meant to touch the inside of the panel when you mount it. You simply have to slip a plastic washer onto the jack’s snout before mounting it to make it fully isolated. The Switchcraft RN112BPC jacks mentioned in the parts list are this way.

This space intentionally left blank. :)